Fabrication & Machining Section

The fabrication shop is equipped with MIG, TIG welding, grinding machines, Cutting machines, Our Machine shop is highly equipped with the latest, state art of technologies such as CNC machining center’s, Turning lathes, Vertical machining centers, Drilling machines, Horizontal Boring Machines, Honing machines, Milling machines for carrying out machining works.

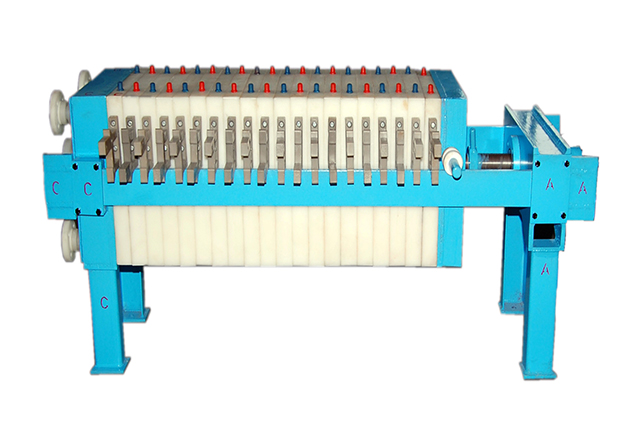

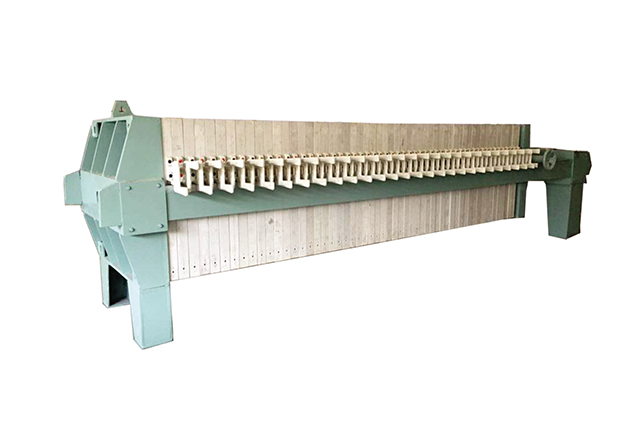

Assembly Section

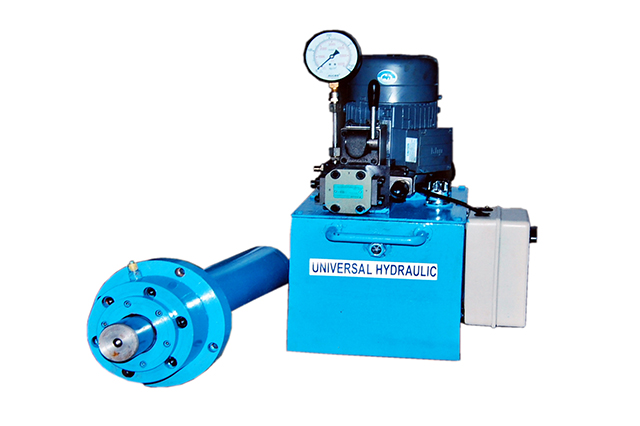

The assembly unit consists of 2 sections: Machine assembly unit & Hydraulic assembly unit. In the hydraulic assembly section, the hydraulic power pack is assembled. The hydraulic cylinder is manufactured, honed, and assembled to the Hydraulic head of the machine. They are available with mechanical locking as well as an automatic pressure compensation system, with a stroke length ranging from 150 mm to 5000 mm. The Cylinder is designed for various sizes of Filter Press depending upon the Pressure ranging from 10 tons to 400 tons.

Testing & Inspection

Filter press structure and PP plates are dimensionally checked before dispatch to assure no deviations and the Filter press machine is subjected to a mechanical load test to a maximum pressure of 315 bar to check if any pressure drops or leakage .

INFRASTRUCTURE & MANUFACTURING FACILITIES

Building dreams

Our products are all manufactured under one roof. our production department is well segregated into following sections:-Fabrication & Machining Section,Assembly Section ,Testing & Inspection .